Product Details

Turnover pallet

Category:

Mob:+86-13766160956

Email:LZ@xinjiazhe.com

Keywords:

Injection molded products

Product Details

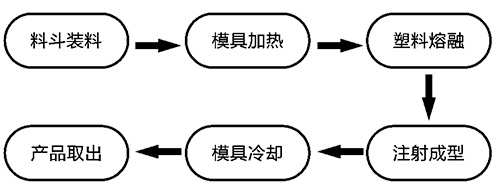

Manufacturing Process

I. The injection molding process mainly includes 5 stages: mold clamping, filling, pressure holding, cooling, and demolding. Injection molding is characterized by short production cycles, high automation, and the ability to produce products with complex shapes and precise dimensions.

II. Arrange the layout according to the injection molding production process to ensure close connection between each workstation and reduce material handling distance and time.

III. Reasonably plan the production line's footprint, make full use of space resources, and improve site utilization.

IV. Consider factors such as equipment safety and personnel operational safety to ensure that the production line layout meets safety production requirements. The production line layout should have a certain degree of flexibility to adapt to future market demand changes and production process adjustments.

Product Advantages

I. Fast production speed and high efficiency: The injection molding process is very fast, with each molding cycle taking only about 15-120 seconds. This allows for the production of more injection molded parts within a given production time, thereby improving overall production efficiency.

II. Suitable for mass production: Injection molding is highly suitable for mass production, capable of manufacturing millions of nearly identical parts while maintaining high consistency.

III. Complex part design: Injection molding can handle highly complex part designs, providing consistency and enabling high-quality manufacturing of parts without sacrificing complexity.

IV. Material and color flexibility: The injection molding process offers flexibility, allowing for a variety of material and color options to meet specific project requirements. Furthermore, by adjusting plastics, additives, and biocompatibility, desired colors and properties can be achieved.

V. High strength: The strength and durability of modern lightweight thermoplastics have significantly improved, even comparable to metal parts, and in some cases, exceeding metal.

VI. Reduced waste: The injection molding process generates very little post-production waste. Any unused plastic can be reground and recycled for future use, thereby reducing waste.

Production Process

Recommended Products

Online Message

If you are interested in our products, please leave us a message. We look forward to serving you.